SMC's Intermediate Bore Sizes: Revolutionizing Energy Efficiency in Pneumatic Systems

- Elvira Rakova

- Jul 28, 2023

- 3 min read

Updated: Aug 31, 2023

In the realm of pneumatic systems, engineers have long relied on the convenience of ISO cylinder sizing based on the Renard number system. This straightforward approach simplifies design and manufacturing processes, but there's a haunting truth lurking beneath the surface: our pursuit of energy efficiency has been compromised. As we stand at the cusp of a new era driven by sustainability, it's time to shed light on the glaring inefficiencies of this traditional practice.

1. The Renard Numbers: A Blast from the Past

Introduced in the 1800s by the ingenious French engineer Charles Renard, the Renard number system offered a geometric progression in ISO for various industries, including pneumatics... It is used for standardized cylinder bore sizes. Multiply the current bore size by 1.259, and you get the next standard size:

8, 10, 12, 16, 20, 25, 32, 40, 50, 63, 80,100, and 120 mm. While this system revolutionized design and manufacturing in its time, we must recognize that times have changed, and so have our energy needs.

2. The Energy Efficiency Paradox

As the world witnesses an ever-increasing demand for efficient technologies, the static nature of ISO cylinder bore sizes becomes an alarming paradox. Our pursuit of greener and more sustainable practices clashes with the inefficiencies perpetuated by the Renard number system.

For instance, a 50 mm cylinder consumes a staggering 30% more energy than a 40 mm one operating under the same pressure level, defying the very essence of energy-conscious engineering.

For more on the cylinder sizing watch our video on the #noboringpneumatic YouTube channel.

But what if we need only 800 N force? The force gap between cylinders is about 40%! And the user has to pay 30% for unnecessary force. Of course, we can reduce the pressure level, but to really reduce the cost, it has to be adjusted at the compressor level.

3. Rethinking Efficiency: A Call to Action

In the face of pressing environmental challenges, we cannot afford to turn a blind eye to the wastefulness of traditional cylinder sizing. As engineers, manufacturers, and consumers, we must take an active role in rethinking efficiency and embracing innovations that align with our eco-conscious aspirations.

4. Bridging the Gap: The Need for Customization

To bridge the chasm between engineering ease and energy efficiency, a paradigm shift is imperative. One-size-fits-all solutions no longer hold merit. It's time to explore customization in pneumatic systems, including intermediate bore sizes that fill the gaps in the Renard sequence. This approach allows us to optimize energy consumption without sacrificing performance.

5. Solution: SMC's Intermediate Bore Sizes: Revolutionizing Energy Efficiency in Pneumatic Systems

SMC, a leading manufacturer of pneumatic components, has introduced a game-changing innovation to bridge the gap in energy consumption. By offering intermediate bore sizes - 45 (Equiv. ø32 x 2 piston area), 57 (Equiv. ø40 x 2 piston area), and 71 (Equiv. ø50 x 2 piston area) - SMC redefines ISO cylinder sizing for improved efficiency without compromising system performance. Let's explore how this breakthrough is transforming the pneumatic industry.

So let's see if we need a force of 800 N, what are the choices we have?

6. Embracing a Sustainable Future

In the pursuit of a sustainable future, pneumatic technologies must evolve with our changing world. By adopting greener alternatives, leveraging modern materials, and integrating advanced control systems, we can redefine efficiency in pneumatic systems.

7. Making efficiency accessible to everyone

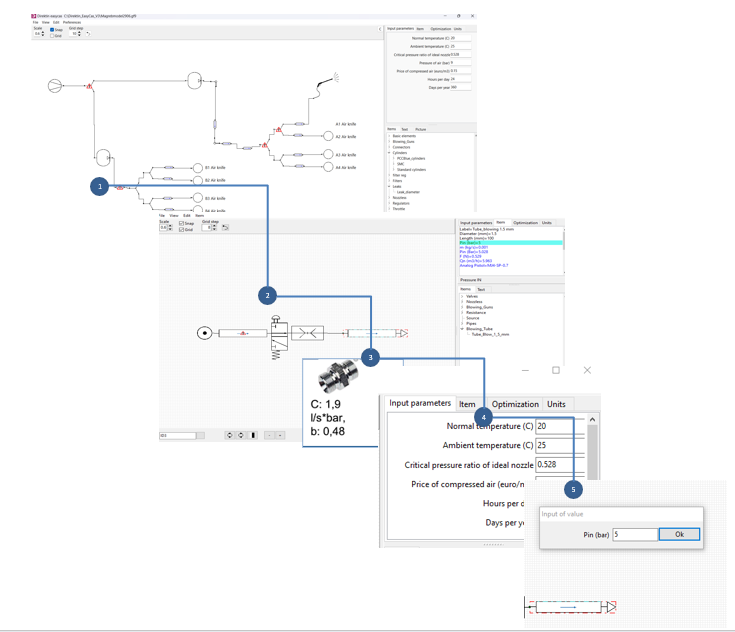

We are thrilled to introduce you to our exceptional software, meticulously developed by Direktin, designed to bring unparalleled efficiency to your design process. Experience a new level of streamlined excellence as you bid farewell to time-consuming manual calculations. Embrace the power of innovation with SMC cylinder integration, enabling you to optimize your operations effortlessly.

But our vision extends far beyond individual benefits. At Direktin, we are driven by a profound commitment to making energy efficiency accessible to all. Our unwavering dedication to sustainability empowers businesses and individuals alike to reduce waste and drive progress toward a greener world.

In line with our mission, we invite pioneering suppliers to join forces with us in the #airgymovement. By integrating your revolutionary solutions into the Direktin platform, together, we can create an unparalleled ecosystem that propels us toward a more sustainable and efficient future.

.

Download the model shown in the tutorial to test it for different applications.

Simply open the EasyCas software and load the new project "Cylinders_SMC".

Comments